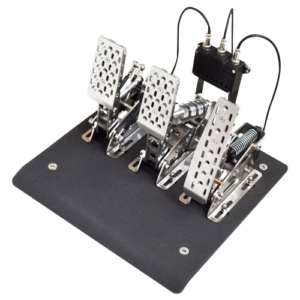

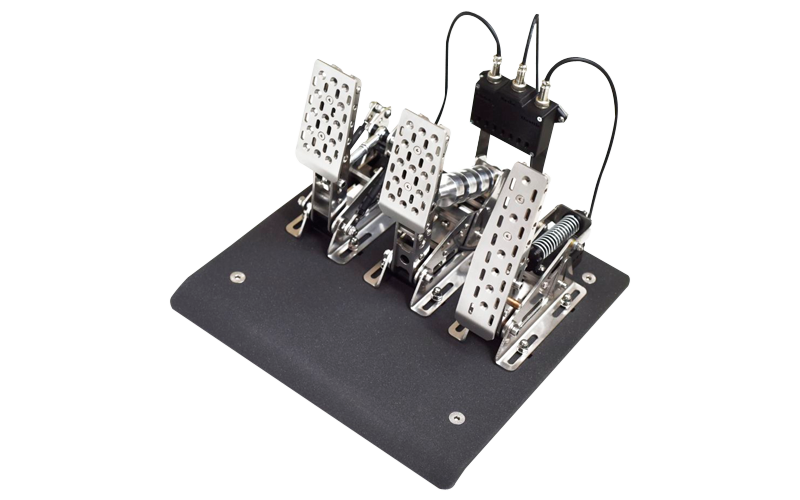

Meca CUP1 2 pedal set

The first professional SIM RACING pedals made in Czech republic. It is a pedal set equipped with a brake pedal with built-in “Load Cell” technology for ultra-precision braking in racing games. Baseplate not included.

The material used for the manufacture of the pedals is 3mm thick stainless steel. Stainless steel class 1.4301.

Swivel and sliding bearings are made from bronze sliding segments, unibals on rods are used from the Automotive environment (stainless steel, aluminum, brass).

The rods are made of stainless steel logs with lathed threads. Each of the three pedals are equipped with a Loadcell sensor. The brake pedal is equipped with a 200kg sensor.

Hay existencias

Electronic sensors

Leo Bodnar, 16 bit. PC connection via USB cable,Plug and Play.

Calibration via DIVIEW software, leobodnar.com

The baseplate is made out of 8mm thick metal sheet which is powder coated. Attachement to the rig is through prepared holes, as per estabilished manufacturers. The grooves allow pedal positioning. The stainlesssteel parts are laser cutted with a CNC laser. Pedals are treated with ballotina (shot-peening).

Lathed parts: bronz mounting of each pedal, stainless thredded beams, Alu. brake segments, bronze thtottle pedal stops.

3D print

Material PETG, electronics boxes, delimitation between unibals in pedal lever, gas spring preload.

Screws and all connection materials

Stainless steel type A2.

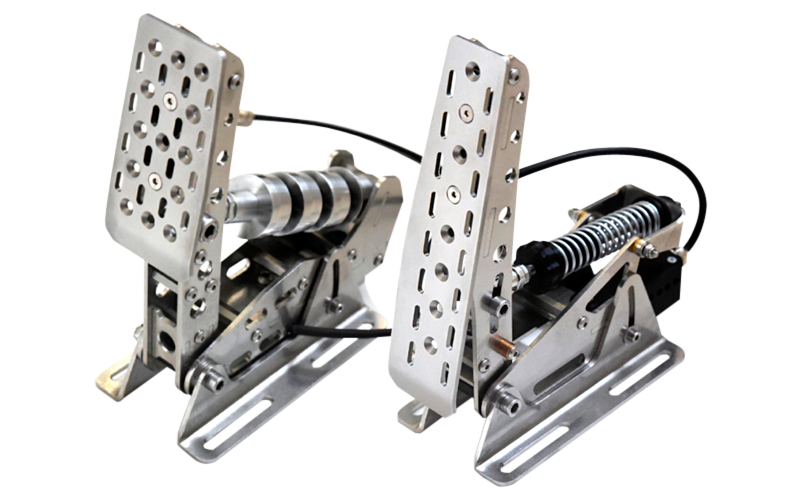

THROTTLE pedal

- Stainless steel construction

- Bronze slide bearings

- Loadcell sensor

- Board for signal conversion from loadcell (analog-digital)

Very strong construction, no unwanted movements or squeaks.

Excellent response to foot with adjustable personal preferences.

Made to last through the usage of loadcells, quality materials, electronics and bronze lathed components.

Pedal can be tilted forwards by loosening the rear screws in the round groove in the rear of the pedal. The grooves allow the pedal to tilt by 18°.

The pedal height can be adjusted at the front part or by moving the remote posts in the rear. The shape and length of the pedal is adapted for the Heel and Toe technique.

Stiffness of the pedal can be also adjusted by moving the unibal in the groove of the pedal lever (main stiffness setting) and fine-tune the stiffness with the locking wheel that pre-tensiones the spring.

The pedal surface is treated with ballotin (glass blasting), which increases the adhesion.

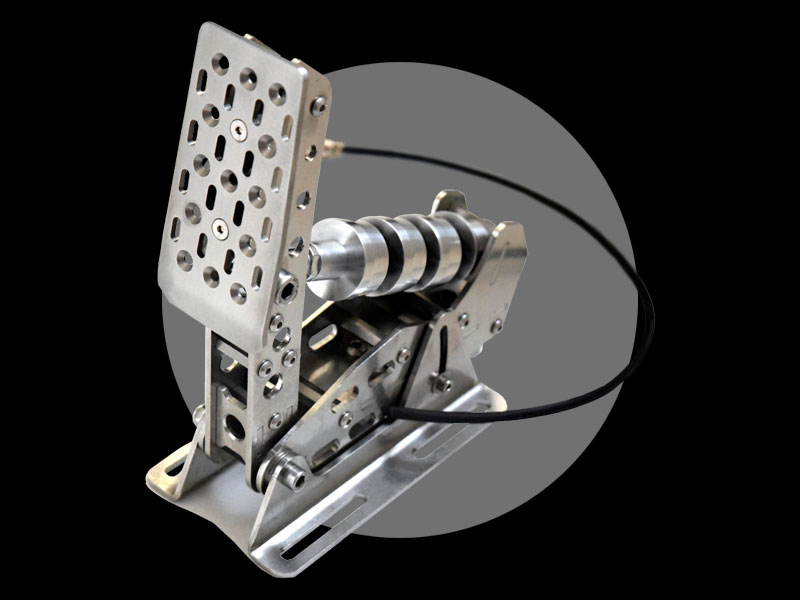

BRAKE pedal

- Stainless steel

- Loadcell sensor 200Kg

- Bronze slide bearings

- Aluminum brake segments

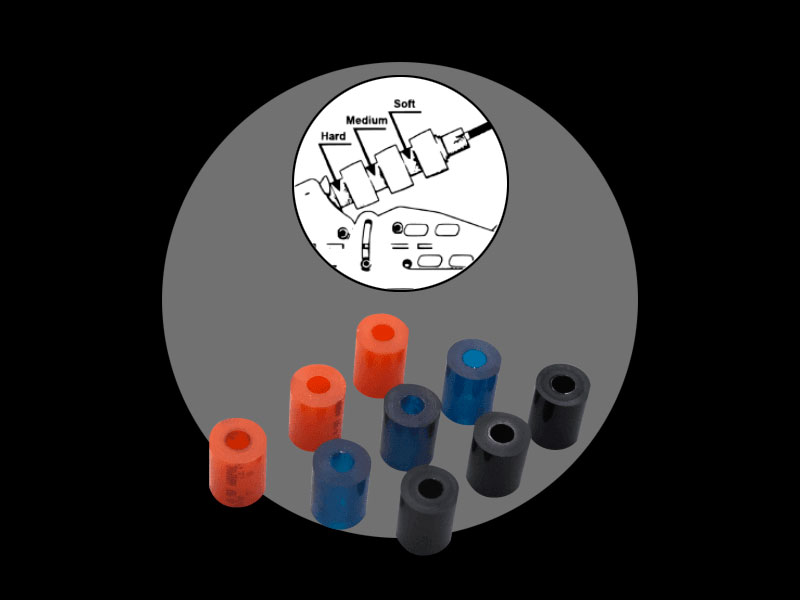

- Three different hardness of replaceable polyurethanes

- The pedal can be adjusted both in height and longitude

Very strong construction, no unwanted movements or squeaks.

Excellent response to foot with adjustable personal preferences.

Made to last through the usage of loadcells, quality materials, electronics and bronze lathed components.

Pedal can be tilted forwards by loosening the rear screws in the round groove in the rear of the pedal. The grooves allow the pedal to tilt by 18°.

The pedal height can be adjusted at the front part or by moving the remote posts in the rear. The shape and length of the pedal is adapted for the Heel and Toe technique.

Stiffness of the pedal can be also adjusted by moving the unibal in the groove of the pedal lever (main stiffness setting) and fine-tune the stiffness with the locking wheel that pre-tensiones the spring.

The pedal surface is treated with ballotin (glass blasting), which increases the adhesion.

Replaceable polyurethane rollers for pedal hardness adjustment

Package includes rollers of three levels of hardness : black – soft (mounted to the pedal), blue – middle, orange – hard. By exchanging and combining the rollers with different hardness levels you can alternate from a soft pedal with a certain travel to a pedal that is extremely stiff with minimal travel. Rollers can be also combined to enable different options. For example; black, blue, orange which affects the linearity of stiffness when pressing the pedal.

Aluminum polyurethane stoppers

Each polyurethane is equipped with its own stopper (aluminum bowl). This ensures that each polyurethane is protected against its marginal limit load and further increase the modularity of the entire system. Explanation: Polyurethane rollers can be loaded until their weight load limit. Once the limit is breached the rollers become kegs and the attached sensors are no longer capable of reading the force applied to the pedal as the force is expelled out of the axis. This results in excessive deformation, feeling of unpleasant pedal drop and in particular in a reduction in the life expectancy of the roller.

Another important benefit occurs when the stoppers connect when fully pressing the break pedal simulating an entire pressurized break system with no more pedal movement. This leads to a hard break pedal resulting in a very similar feeling to breaking in a real car.

Stoppers therefore prevent excessive deformation, significantly extend the lifespan of the polyurethanes and contributes to a overall better braking feeling.

Strong construction, easily replaceable polyurethane rollers, excellent feeling when breaking, quality 100Kg Loadcell.

PEDALS Base-plate

- 8mm thick steel plate

- Powder lacquered

- Grooves enabling adjustment of the pedals positions

- Pedals are attached to the rig by 4 screws M8 and M6

- Preparation for the assembly of the main electronic box